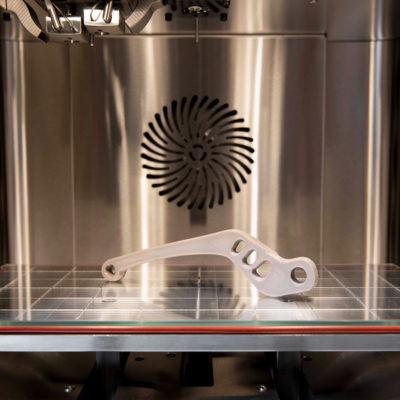

MINIFACTORY ULTRA – INDUSTRIAL 3D PRINTER

MINIFACTORY ULTRA

INDUSTRIAL 3D PRINTER

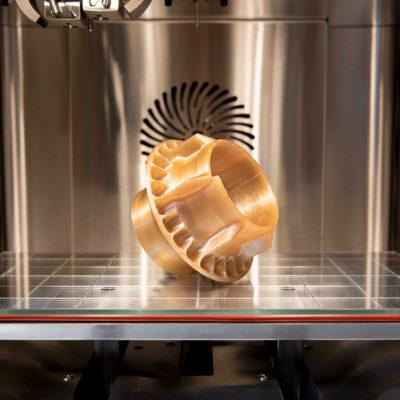

Harness the power of ultra polymers with miniFactory Ultra

The most powerful and versatile industrial 3D printer.

With this all-in-one device you have the whole material range available.

ULTEM®, PEKK, PPSU, PA-CARBON, PEEK, and many more at your disposal.

For the professionals whom the quality matters.

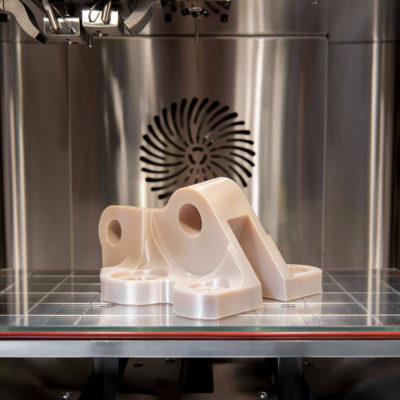

ULTIMATE STRENGTH AND QUALITY

WITH 250°C HEATED CHAMBER

Extremely high temperature in the chamber unlocks

the widest material range on the market and ensures

ultimate strenght for printed parts.

AARNI – PROCESS MONITORING SYSTEM

Cutting-edge process monitoring system does the quality

control for you. Let the system supervise itself and

certify your prints unlike ever before.

HEATED FILAMENT CHAMBER

High-performance polymers are extremely sensitive

for the humidity. Ultra’s Heated Filament Chamber

ensures the optimal condition for your materials.

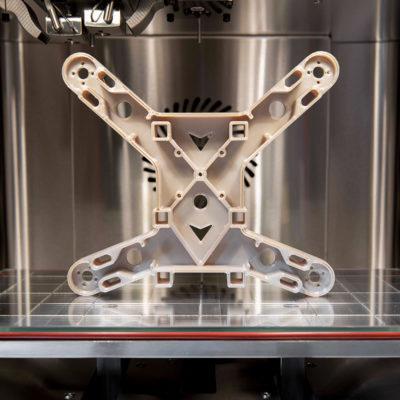

SERVO DRIVEN TECHNOLOGY

Presicion and stability with high-end servo motors,

ball screws and linear guides ensure large, dimensionally

accurate and repeatable prints.

One of the most accurate FFF printing systems available.

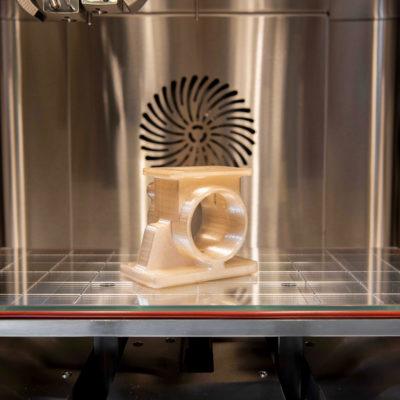

AUTOMATE POST-PROCESSING

miniFactory Ultra’s post-processing features are activated

straight from the touch screen, providing optimized annealing

process to the selected material.

No need for separate post-processing equipment.

ACTIVE CARBON FILTERING

miniFactory is a pioneer in printing safety.

The filtering will considerably reduce the amount of

emissions present in the printing process of industrial polymers.

Office friendly system

KEY FEATURES

- Ultimate strength with heated chamber up to 250°C

- Large print size with 330 x 180 x 180 mm build area

- Versatility with ultra polymers like ULTEM, PEEK, PEKK, PPSU, PA

- High nozzle temperature up to 470°C

- Extreme printing quality with AC Servo motors

- Quality assurance by AARNI Process Monitoring System

TECHNICAL DATA

- Device measurements: 100 x 80 x 190 cm

- Device weight: 320 kg

- Power requirements: 400V/16A 3-PHASE

- Certification: CE

ADDITIONAL FEATURES

- Fully automatic calibration – optimal first layer adhesion

- Separable dual extruder – cleaner printing result

- Large 7” touch screen – easy to operate

- Vacuum table – easy & fast build platform change

- Activated carbon filtering – considerably reduce the amount of emissions