Form Wash + Form Cure

Form Wash

&

Form Cure

Stronger Parts, Less Effort

Automate Cleaning with Form Wash

Parts travel straight from the Form 2 to Form Wash. Opt to go glove-free and keep parts directly on the build platform.

Set it and Forget it

Simply set the appropriate time and let Form Wash get to work.

15

MINUTES

Approximate wash time when using fresh isopropyl alcohol (IPA)

8.6

LITERS

IPA volume for removeable wash bucket

70

PRINTS

Amount of prints per IPA refill in regular use

While you’re away, parts are precisely agitated in IPA,

getting every nook and cranny perfectly clean.

A Consistent, Automated Workflow

Once washing completes, Form Wash automatically lifts parts out of the IPA, avoiding over-soaked, warped prints. Parts air dry and are ready when you are.

Included with Form Wash

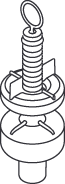

HYDROMETER

A custom hydrometer tool to check IPA saturation.

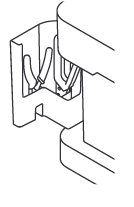

STORAGE

Behind the wash bucket to keep finishing tools tidy.

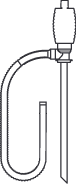

SIPHON PUMP

Easy IPA transfer into and out of the wash bucket.

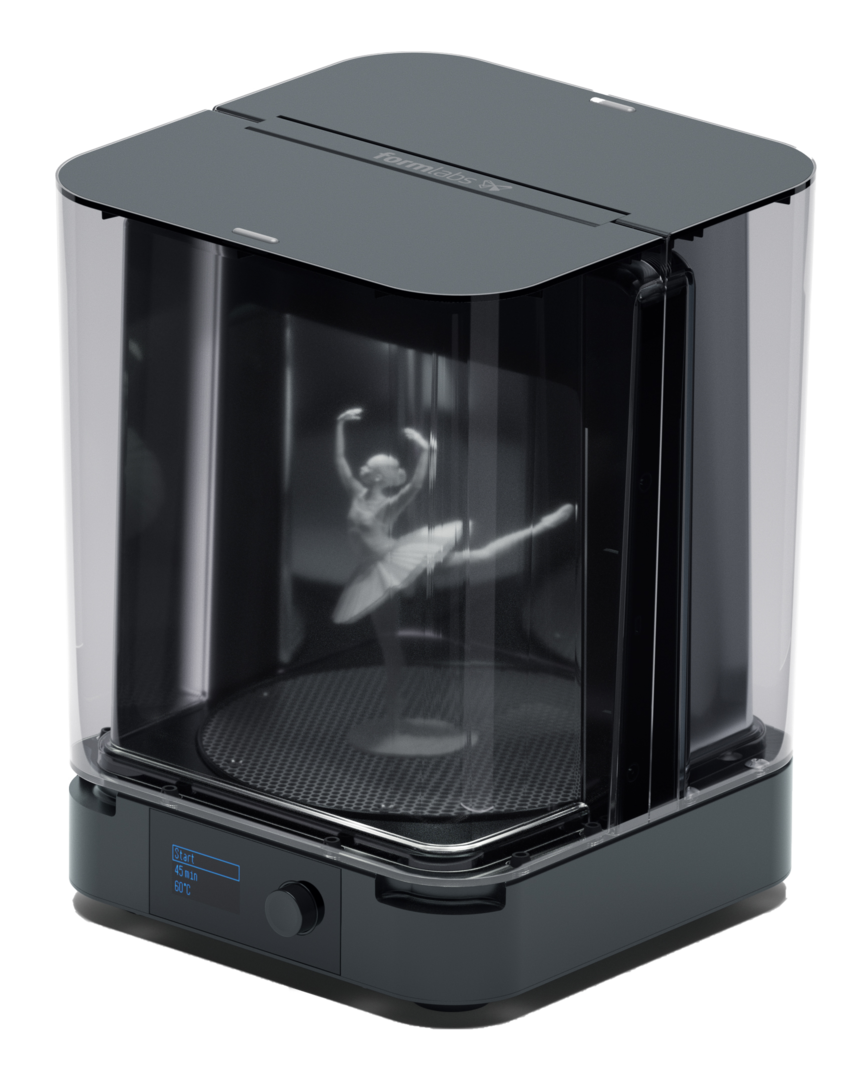

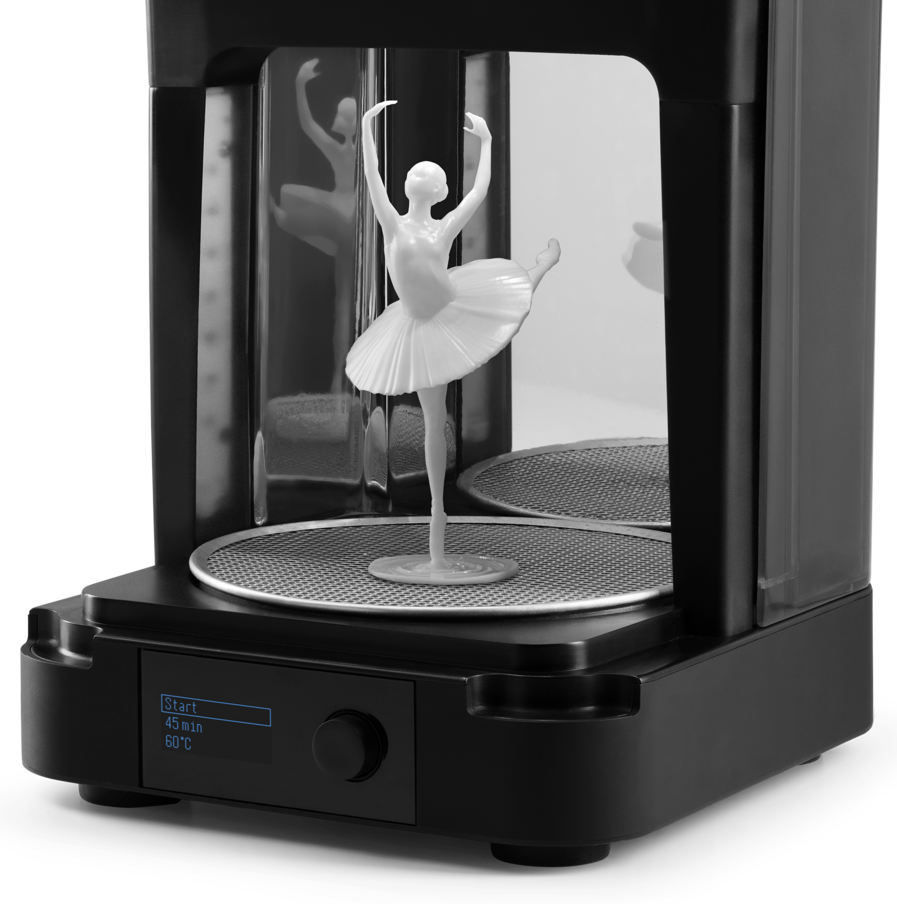

Unlock Peak Performance

Form Cure is finely tuned to bring parts to their maximum mechanical properties.

80

DEGREES CELSIUS

An advanced heating system precisely controls curing temperatures up to 80° C

405

NANOMETERS

13 multi-directional LEDs emit the optimal wavelength of light for curing Formlabs materials

1

REVOLUTION PER MINUTE

A rotating turntable provides uniform exposure during post-curing

Form Cure’s turntable rotates to provide uniform exposure.

The heating system preheats the chamber to get parts ready for optimum post-curing.

Once the chamber is heated, 13 LEDs trigger the post-curing reaction, bringing parts to their maximum mechanical properties.

Reliable, Professional Post-Curing

Once time is up, parts are fully cured and ready for peak performance.

Complete Your 3D Printing Experience

Add Form Wash and Form Cure to your SLA engine.