Formlabs Fuse 1+ 30W

Formlabs Fuse 1+ 30W: Ισχυρή και Προσιτή SLS Τεχνολογία

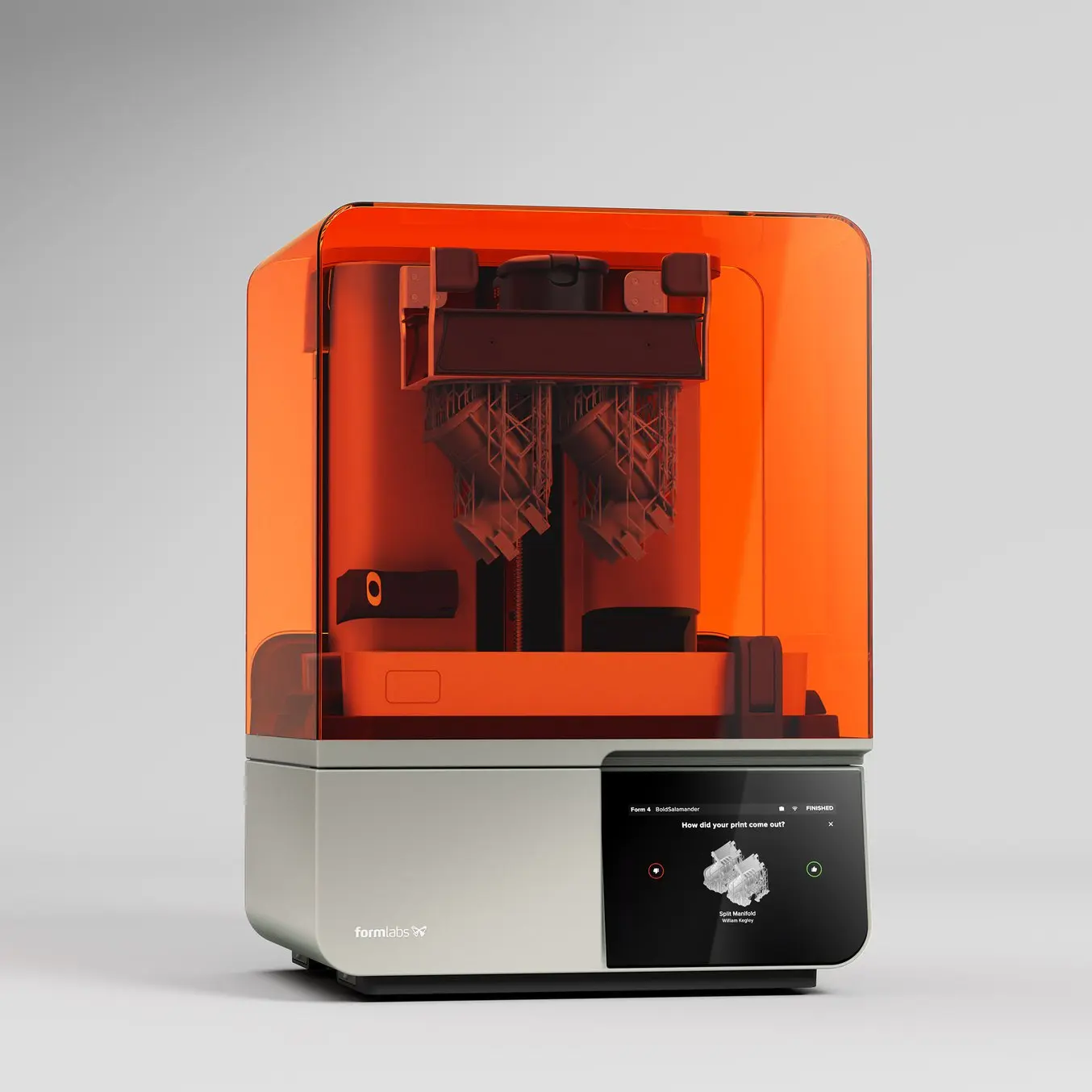

Το Fuse 1+ 30W είναι ο κορυφαίος επιτραπέζιος εκτυπωτής SLS (Selective Laser Sintering) από τη Formlabs, προσφέροντας βιομηχανική απόδοση σε προσιτό κόστος. Με προηγμένο λέιζερ 30W, γρήγορη εκτύπωση και υποστήριξη εξειδικευμένων υλικών, είναι ιδανικό για την παραγωγή λειτουργικών πρωτοτύπων και τελικών προϊόντων.

Λεπτομερής Περιγραφή

Formlabs Fuse 1+ 30W: Βιομηχανική Απόδοση σε Επιτραπέζιο Μέγεθος

Το Formlabs Fuse 1+ 30W φέρνει την επανάσταση στην τεχνολογία SLS, συνδυάζοντας υψηλή ταχύτητα, ακρίβεια και ευκολία χρήσης. Σχεδιασμένο για επαγγελματίες που χρειάζονται αξιόπιστη παραγωγή λειτουργικών πρωτοτύπων και τελικών εξαρτημάτων. Το Fuse 1+ 30W προσφέρει δυνατότητες που προηγουμένως ήταν διαθέσιμες μόνο σε μεγαλύτερα και ακριβότερα συστήματα.

Κύρια Χαρακτηριστικά:

- Ισχυρό Λέιζερ 30W

- Το προηγμένο λέιζερ 30W επιταχύνει τις εκτυπώσεις, επιτρέποντας ταχύτερη παραγωγή χωρίς συμβιβασμούς στην ακρίβεια ή την αντοχή των εξαρτημάτων.

- Ευελιξία Υλικών

- Υποστηρίζει εξειδικευμένα SLS υλικά, όπως Nylon 12, Nylon 11 και Carbon Fiber-Reinforced Nylon 11, για εφαρμογές που απαιτούν αντοχή, ευκαμψία και θερμική αντίσταση.

- Επαναχρησιμοποίηση Πούδρας

- Με δυνατότητα επαναχρησιμοποίησης έως και 70% της πούδρας, μειώνει τα απόβλητα και το κόστος παραγωγής.

- Υψηλή Ταχύτητα Εκτύπωσης

- Το αναβαθμισμένο σύστημα ροής αερίου και η ισχυρή θερμική διαχείριση μειώνουν σημαντικά τον χρόνο εκτύπωσης, αυξάνοντας την παραγωγικότητα.

- Εύχρηστος Σχεδιασμός

- Με εργονομικό σχεδιασμό και απλό περιβάλλον χρήστη, επιτρέπει την εύκολη προετοιμασία και διαχείριση εκτυπώσεων, ακόμα και από αρχάριους.

- Formlabs Fuse Sift: Καθαρή και Αποτελεσματική Μετά-Επεξεργασία

- Σε συνδυασμό με το Fuse Sift, το Fuse 1+ 30W προσφέρει ολοκληρωμένη διαχείριση και επεξεργασία της πούδρας, διασφαλίζοντας καθαρότητα και ακρίβεια σε κάθε βήμα.

- Αξιοπιστία και Επανάληψη

- Η τεχνολογία SLS του Fuse 1+ 30W προσφέρει εξαρτήματα με ισοτροπικές ιδιότητες και κορυφαία αντοχή, ιδανικά για μηχανολογικές και βιομηχανικές εφαρμογές.

Ιδανική Επιλογή για Επαγγελματίες

Το Fuse 1+ 30W καλύπτει ευρύ φάσμα εφαρμογών, όπως:

- Μηχανολογικά Πρωτότυπα: Αντοχή σε δοκιμές και μηχανικές καταπονήσεις.

- Τελικά Προϊόντα: Παραγωγή μικρών σειρών τελικών εξαρτημάτων.

- Εξαρτήματα Υψηλών Απαιτήσεων: Αντοχή σε θερμοκρασίες και χημικές καταπονήσεις.

Η Προσιτή Επανάσταση στην SLS Τεχνολογία

Το Formlabs Fuse 1+ 30W φέρνει την ισχύ της βιομηχανικής παραγωγής στα χέρια μικρών και μεσαίων επιχειρήσεων. Συνεπώς προσφέρει μια μοναδική ισορροπία κόστους, ποιότητας και ταχύτητας.

Ανακαλύψτε το Fuse 1+ 30W και μεταμορφώστε την παραγωγή σας σήμερα!

Μόνο συνδεδεμένοι πελάτες που έχουν αγοράσει αυτό το προϊόν μπορούν να αφήσουν μία αξιολόγηση.

Λεπτομερής Περιγραφή

Formlabs Fuse 1+ 30W: Βιομηχανική Απόδοση σε Επιτραπέζιο ΜέγεθοςΤο Formlabs Fuse 1+ 30W φέρνει την επανάσταση στην τεχνολογία SLS, συνδυάζοντας υψηλή ταχύτητα, ακρίβεια και ευκολία χρήσης. Σχεδιασμένο για επαγγελματίες που χρειάζονται αξιόπιστη παραγωγή λειτουργικών πρωτοτύπων και τελικών εξαρτημάτων. Το Fuse 1+ 30W προσφέρει δυνατότητες που προηγουμένως ήταν διαθέσιμες μόνο σε μεγαλύτερα και ακριβότερα συστήματα.Κύρια Χαρακτηριστικά:

- Ισχυρό Λέιζερ 30W

- Το προηγμένο λέιζερ 30W επιταχύνει τις εκτυπώσεις, επιτρέποντας ταχύτερη παραγωγή χωρίς συμβιβασμούς στην ακρίβεια ή την αντοχή των εξαρτημάτων.

- Ευελιξία Υλικών

- Υποστηρίζει εξειδικευμένα SLS υλικά, όπως Nylon 12, Nylon 11 και Carbon Fiber-Reinforced Nylon 11, για εφαρμογές που απαιτούν αντοχή, ευκαμψία και θερμική αντίσταση.

- Επαναχρησιμοποίηση Πούδρας

- Με δυνατότητα επαναχρησιμοποίησης έως και 70% της πούδρας, μειώνει τα απόβλητα και το κόστος παραγωγής.

- Υψηλή Ταχύτητα Εκτύπωσης

- Το αναβαθμισμένο σύστημα ροής αερίου και η ισχυρή θερμική διαχείριση μειώνουν σημαντικά τον χρόνο εκτύπωσης, αυξάνοντας την παραγωγικότητα.

- Εύχρηστος Σχεδιασμός

- Με εργονομικό σχεδιασμό και απλό περιβάλλον χρήστη, επιτρέπει την εύκολη προετοιμασία και διαχείριση εκτυπώσεων, ακόμα και από αρχάριους.

- Formlabs Fuse Sift: Καθαρή και Αποτελεσματική Μετά-Επεξεργασία

- Σε συνδυασμό με το Fuse Sift, το Fuse 1+ 30W προσφέρει ολοκληρωμένη διαχείριση και επεξεργασία της πούδρας, διασφαλίζοντας καθαρότητα και ακρίβεια σε κάθε βήμα.

- Αξιοπιστία και Επανάληψη

- Η τεχνολογία SLS του Fuse 1+ 30W προσφέρει εξαρτήματα με ισοτροπικές ιδιότητες και κορυφαία αντοχή, ιδανικά για μηχανολογικές και βιομηχανικές εφαρμογές.

Ιδανική Επιλογή για Επαγγελματίες

Το Fuse 1+ 30W καλύπτει ευρύ φάσμα εφαρμογών, όπως:- Μηχανολογικά Πρωτότυπα: Αντοχή σε δοκιμές και μηχανικές καταπονήσεις.

- Τελικά Προϊόντα: Παραγωγή μικρών σειρών τελικών εξαρτημάτων.

- Εξαρτήματα Υψηλών Απαιτήσεων: Αντοχή σε θερμοκρασίες και χημικές καταπονήσεις.

Η Προσιτή Επανάσταση στην SLS Τεχνολογία

Το Formlabs Fuse 1+ 30W φέρνει την ισχύ της βιομηχανικής παραγωγής στα χέρια μικρών και μεσαίων επιχειρήσεων. Συνεπώς προσφέρει μια μοναδική ισορροπία κόστους, ποιότητας και ταχύτητας.Ανακαλύψτε το Fuse 1+ 30W και μεταμορφώστε την παραγωγή σας σήμερα!

Σχετικά προϊόντα με το Formlabs Fuse 1+ 30W...

5,399.00 € με ΦΠΑ

Διαθέσιμο κατόπιν παραγγελίας

10,690.00 € με ΦΠΑ

Διαθέσιμο κατόπιν παραγγελίας

Αξιολογήσεις

Δεν υπάρχει καμία αξιολόγηση ακόμη.