Zortrax Endureal

Τρίτη γενιά βιομηχανικού 3D εκτυπωτή για κατασκευή υψηλής τεχνολογίας

Προηγμένη θερμική διαχείριση που επιτρέπει την αποδοτική εργασία με πολυμερή υψηλής απόδοσης είναι όλα όσα έχουν οι 3D εκτυπωτές τρίτης γενιάς. Η θερμοκρασία των νημάτων στον Zortrax Endureal LPD Plus ελέγχεται αυστηρά σε κάθε στάδιο της επεξεργασίας ώστε να επιτυγχάνεται η μέγιστη ακρίβεια και οι καλύτερες δυνατές μηχανικές ιδιότητες των 3D εκτυπωμένων εξαρτημάτων.

Εξωθητής

υψηλής

θερμοκρασίας

Ένας προηγμένος εξωθητής μπορεί να εργαστεί σε συνεχείς υψηλές θερμοκρασίες για να στηρίξει την επεξεργασία CFR νημάτων, PEEK ή άλλα απαιτητικά πολυμερή.

Θερμαινόμενος θάλαμος εκτύπωσης

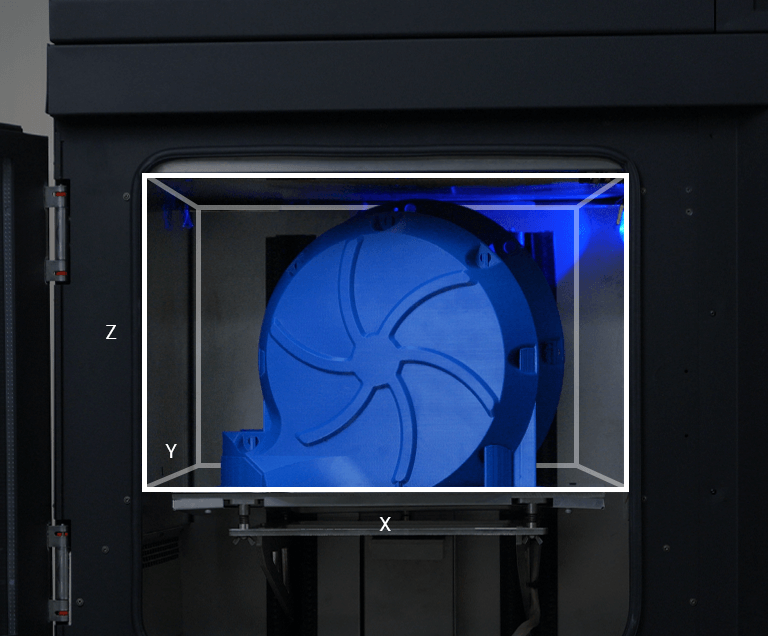

Η θερμοκρασία στο θάλαμο εκτύπωσης μπορεί να επιλεγεί με ακρίβεια για την επίτευξη των καλύτερων μηχανικών ιδιοτήτων σε υλικά υψηλής θερμοκρασίας.

θερμαινόμενη πλατφόρμα χτισίματος

Μια πλατφόρμα χτισίματος μπορεί να στηρίξει θερμοκρασίες κατάλληλες για πολυμερή υψηλής απόδοσης.

Προηγμένη θερμική θωράκιση

Το θερμο-θωρακισμένο τμήμα των εξωθητών διατηρείται πάντα σε χαμηλές θερμοκρασίες για να εξασφαλιστεί η αδιάκοπη μεταφορά νημάτων.

Θερμαινόμενο τμήμα νημάτων

Τα νήματα αποθηκεύονται σε ένα κλειστό τμήμα σε βέλτιστη θερμοκρασία και υγρασία.

Βιομηχανικά ασφαλή συστήματα

Ο Zortrax Endureal διαθέτει 17 ενσωματωμένους αισθητήρες που δουλεύουν σε πραγματικό χρόνο για να διασφαλίσουν η αδιάκοπη λειτουργία σε έργα υψηλής τεχνολογίας και ανάπτυξης προϊόντων.

Σύστημα απόκρισης διακοπής ρεύματος

Όταν ανιχνευτεί μια διακοπή ρεύματος, ο Endureal χρησιμοποιεί την ενέργεια που αποθηκεύεται σε ενσωματωμένους πυκνωτές για να αποθηκεύσει την ακριβή θέση της κεφαλής εκτύπωσης. Με αυτόν τον τρόπο, η εκτύπωση μπορεί να επαναληφθεί από το ίδιο σημείο, όταν το ρεύμα έρθει ξανά.

Προηγμένοι αισθητήρες νημάτων

Ξεχωριστοί αισθητήρες λειτουργούν ανά πάσα στιγμή για να ανιχνεύουν συμβάντα όταν το νήμα έχει μπλοκάρει ή εξαντληθεί. Ο εκτυπωτής παρακολουθεί επίσης το βάρος των καρουλιών νημάτων για να προσδιορίσει εάν υπάρχει αρκετό υλικό για την ολοκλήρωση της διαδικασίας εκτύπωσης.

Παρακολούθηση προόδου εκτύπωσης

Η πρόοδος εκτύπωσης μπορεί να παρακολουθείται απομακρυσμένα με μια κάμερα εγκατεστημένη στο θάλαμο εκτύπωσης του Endureal. Η κάμερα είναι ικανή για ζωντανή μετάδοση βίντεο και έχει σχεδιαστεί για να λειτουργεί σε συνθήκες λειτουργίας υψηλής θερμοκρασίας.

Τμήμα ελεγχόμενων νημάτων

Τα νήματα αποθηκεύονται σε κλειστό περιβάλλον σε βέλτιστη θερμοκρασία. Ένας ενσωματωμένος απορροφητής υγρασίας είναι υπεύθυνος για τη μείωση της υγρασίας σε επίπεδα κατάλληλα για εξαιρετικά υδρόφιλα υλικά.

Βιομηχανικός όγκος χτισίματος

Απόδοση υπό έλεγχο

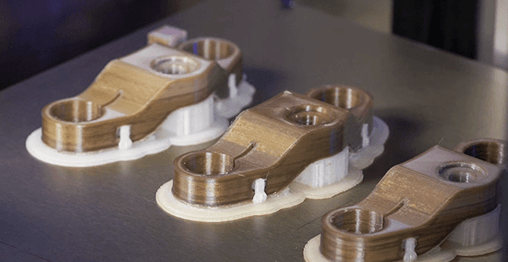

PEEK για τρίτης γενιάς παραγωγή πρόσθετων

σε βιομηχανίες υψηλής τεχνολογίας

Πολυμερή υψηλής τεχνολογίας όπως το PEEK χρησιμοποιούνται για την κατασκευή εξαρτημάτων με προηγμένα χαρακτηριστικά, όπως:

Βιομηχανική διπλή εξώθηση

Ο Endureal διαθέτει ένα προηγμένο σύστημα διπλής εξώθησης ικανό να εκτυπώνει νήματα υψηλής θερμοκρασίας με διαλυτές δομές στήριξης. Τα εξαρτήματα εξώθησης και τα καλώδια από νήμα είναι θερμικά θωρακισμένα από το θάλαμο χτισίματος από ένα ελαστικό μονωτήρα με μέγεθος πόρων μικρότερο από τη μέση ελεύθερη διαδρομή των σωματιδίων αέρα για να επιτευχθεί η χαμηλότερη δυνατή θερμική αγωγιμότητα.

Διπλή εξώθηση

Διπλή εξώθηση

Μονή εξώθηση

Μονή εξώθηση

Θερμαινόμενη πλατφόρμα χτισίματος αλουμινίου

Ο Endureal διαθέτει μια πλατφόρμα χτισίματος αλουμινίου που μπορεί να ζεσταθεί σε θερμοκρασίες που επιτρέπουν την επεξεργασία πολυμερών υψηλής απόδοσης. Εύκολα εναλλασσόμενη πλάκα χτισίματος κατασκευασμένη από φερριτικό ατσάλι που καλύπτεται με μια ταινία PEI είναι συνδεδεμένη με την πλατφόρμα χτισίματος για να εξασφαλιστεί η σωστή πρόσφυση όλων των υποστηριζόμενων νημάτων. Οι εναλλασσόμενες πλάκες χτισίματος είναι αρκετά ελαστικές για να κάνουν την αφαίρεση του μοντέλου ευκολότερη και ταχύτερη, κάτι το οποίο είναι σημαντικό στην παραγωγή μεγάλου όγκου.

Ολοκληρωμένη προτυποποίηση

Ένα ευρύ φάσμα υλικών που υποστηρίζεται από τον Zortrax Endureal καθιστά δυνατή την μετάβαση από τα πρώιμα πρωτότυπα χαμηλού κόστους στο τελικό εξάρτημα υψηλής απόδοσης χρησιμοποιώντας μία συσκευή παραγωγής.

Βήμα 1: Αρχικός σχεδιασμός

Ένα υψηλής απόδοσης εξάρτημα σχεδιάζεται σε λογισμικό CAD.

Βήμα 2: Αρχικά μοντέλα

Τα αρχικά μοντέλα εκτυπώνονται με υλικά χαμηλού κόστους.

Βήμα 3: Προκαταρκτική αξιολόγηση

Τα αρχικά μοντέλα χρησιμοποιούνται για προκαταρκτική αξιολόγηση.

Βήμα 4: Ρυθμίσεις σχεδιασμού

Ο σχεδιασμός του εξαρτήματος προσαρμόζεται με βάση τα αποτελέσματα της αξιολόγησης.

Βήμα 5: Κατασκευή τελικού εξαρτήματος

Το τελευταίο εξάρτημα εκτυπώνεται με υλικό υψηλής απόδοσης.

Βήμα 6: Μετεπεξεργασία

Οι τεχνικές μετεπεξεργασίας, όπως η ανόπτηση, εφαρμόζονται για την επίτευξη των ιδιοτήτων στόχου του υλικού.

Όντας ένα ολοκληρωμένο βιομηχανικό μηχάνημα, ο Endureal μπορεί να υλοποιηθεί τόσο εύκολα όσο οι Zortrax desktop-class 3D συσκευές. Ευκολονόητο περιβάλλον χρήστη και λογισμικό με προσεκτικά βελτιωμένες ρυθμίσεις προκαθορισμένες για κάθε ειδικό νήμα κάνει τον Endureal έτοιμο να εργαστεί σε πλήρη χωρητικότητα από την πρώτη μέρα. Η ευκολία εφαρμογής επεκτείνεται περαιτέρω στη λειτουργία του εκτυπωτή λόγω του κιτ επιχειρησιακής συνέχειας που περιέχει όλα όσα είναι απαραίτητα για γρήγορη και αποδοτική συντήρηση εντός του σπιτιού.