RIZE SOFTWARE

SOFTWARE

RIZE ONETOUCH

The RIZE slicer has been custom designed from the ground up to generate tool paths for building parts fast without compromising strength. Users can import files in multiple formats, including stl, obj, 3mf, ply, vrml, and fbx or use the SOLIDWORKS plug-in to directly import a model from CAD. Intelligent slicing automatically identifies and handles problems in the imported file, such as incomplete surfaces or mismatching surface boundaries. A simple and intuitive interface lets users rotate, move and scale one or multiple parts on the build bed for printing with automatic support-structure generation. Use the default settings for reliable results or the advanced options to specialize output for unique situations. And, only RIZE ONETOUCH software includes markup features to apply text, graphics and 2D barcodes to parts.

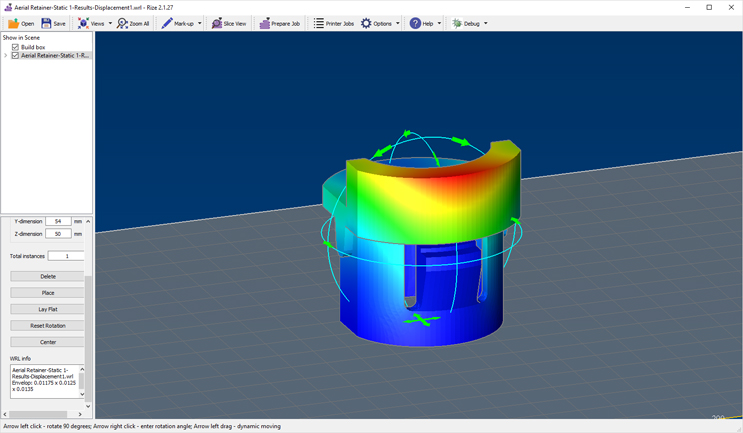

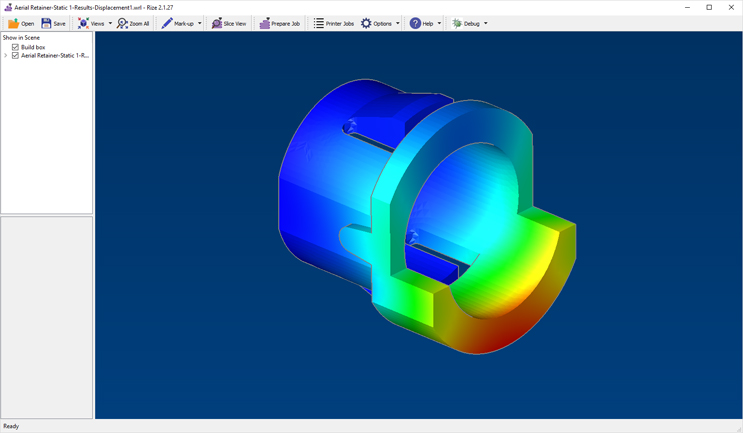

View your part from any angle:

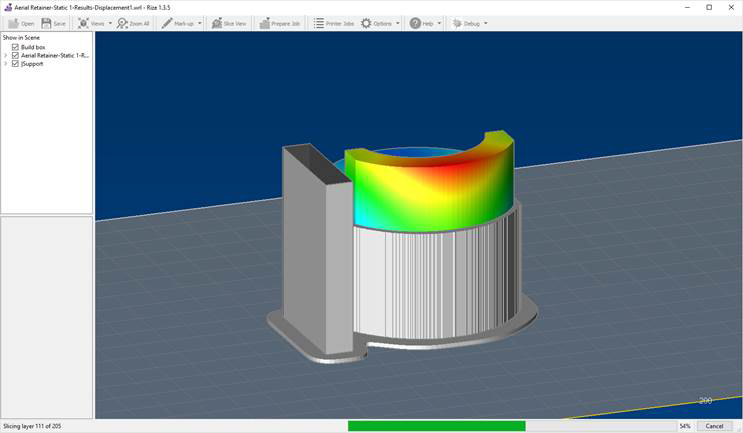

Automatically create the support structure for your part:

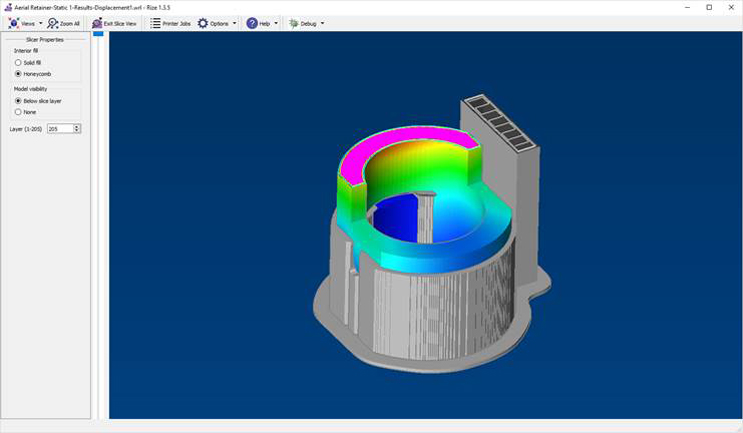

Examine extruder paths, as desired, using a variety of highly detailed print preview options:

RIZE CONNECT

RIZE CONNECT enables users to remotely manage and monitor their RIZE ONE and XRIZE 3D printers from any location to improve production efficiency. Users can receive notifications, queue jobs and manage an enterprise print farm with an intuitive graphical user interface. Using RIZE CONNECT, users can also build greater security into their parts with digital part identification and other forms of part augmentation, such as QR codes and version control for part traceability, compliance and authenticity.