EOS P 500

Build rate of up to 6.6 l/h with a packing density of 5%

Lowest price per part on the market

Automation-friendly platform with standardized software interfaces

Reduced Costs

The innovative layering system, which applies and compacts the material at up to 0.6 m/s, and the two powerful 70-watt lasers reduce the costs per part by more than 30%.

Diversity of Materials

The system processes high-performance plastics, enabling maximum diversity of materials. Application and material development are supported by open software interfaces and user-friendly tools.

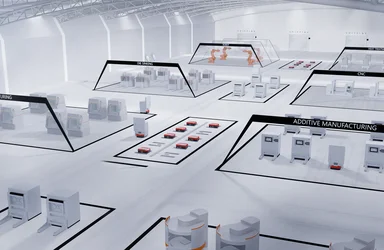

Automation

The system is intuitively controlled by EOSYSTEM. Software integration in CAD systems, e.g. NX™ by Siemens, is provided by EOSPRINT 2, and a connection to ERP systems is provided by EOSCONNECT. Automated interfaces and optimized accessories reduce the cycle time and guarantee operational build times lasting several days.

Technical Data |

||

| Construction Volume | 500 x 330 x 400 mm (19.7 x 13 x 15.7 in) | |

| Laser Type | CO₂, 2 x 70 W | |

| Precision Optics | F-theta lens, surface module, high-speed scanner | |

| Scan Speed | up to 2 x 10 m/sec (32.8 ft/s) | |

| Power Supply | 400 V / 100 A; max. power consumption 80 A | |

| Machine Dimensions (W x D x H) | 3,400 x 2,100 x 2,100 mm (133.9 x 82.7 x 82.7 in) | |

| Recommended Installation Space | min. 7.2 x 5.2 x 4.2 m (284 x 205 x 165 in) | |

| Weight | approx. 7,000 kg (15,432 lb) | |

| Software | EOSYSTEM with EOSAME feature, EOSPRINT 2 with SmartScaling feature and EOS ParameterEditor, EOSCONNECT Core, EOSCONNECT MachinePark, EOSTATE Powderbed |

75%

Uptime

compared to other industrial 3D printers

-25%

Costs per part 25% lower

compared to other industrial 3D printers

40%

Refresh rate

* Depending on packing density, job height, application and the usage of EOS Original Equipment for powder preparation (e.g., IPCMP+)

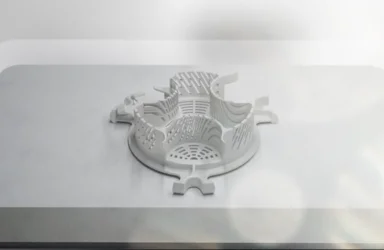

Polymer Materials for the EOS P 500

EOS has exceptional materials expertise and a comprehensive portfolio of highly developed plastic and polymer materials for additive manufacturing. Our materials, systems and process parameters fit together optimally. With the right materials, you can realize the desired property profiles in the best possible way for your products.

PA 2200

The property profile of durable parts made from PA 2200 is very balanced: such parts are characterized by strength, rigidity and good chemical resistance. They are also biocompatible and certified for contact with foodstuffs.

Material Management Plastic Materials

Improve workflow, reduce costs: EOS solutions for material management enable flexible and efficient conveying and screening of plastics.

IPCM P plus

Additive manufacturing in an easy and efficient way to transport and process large quantities of plastic material quickly and safely. The fully automatic solution ensures consistently high material quality and operates a large number of systems.

Big Bag emptying station

The Big Bag emptying station enables practical material conveyance of large quantities of powder of up to 400 kg and thus makes it easier to scale up your production. Improve both the work flow and the quality of your components with a completely closed material cycle.

Software

EOS offers tried-and-tested software solutions for all process steps in additive manufacturing – from the preparation of CAD design data and job preparation to quality control.

EOSCONNECT MachinePark

Expand the capabilities of your EOS system. Increase your productivity with EOS Web Apps and monitor your entire EOS machine park from anywhere in an intuitive dashboard. Receive automatic notifications on machine status and print jobs.

EOSPRINT 2

EOSPRINT is an intuitive, open and productive CAM tool for EOS systems that enables the assignment and optimization of build parameters for your CAD data. Together with data preparation software like SIEMENS NX or Magics, it offers an extensive additive manufacturing CAM environment for a smooth 3D printing process.

EOSCONNECT Core

EOSCONNECT Core is the connectivity solution for monitoring production. EOS systems are IIoT-capable and can be integrated into existing IT infrastructures via EOSCONNECT Core. EOS offers an open interface for this.