EOS M 290

In a nutshell

The most extensive materials portfolio on the market

Powerful 400-watt fiber laser for excellent detail resolution

A robust and well-established system with a vast range of applications

Reproducible Part Quality

The exceptionally high beam quality of the laser spot and the excellent detail resolution are ideal for producing highly complex components with homogeneous properties.

Broad Portfolio of Materials

With the most extensive range of validated materials and processes available on the market, all customer needs are covered.

Comprehensive Quality Management

The comprehensive monitoring suite enables quality assurance of all production- and quality-relevant data in real time.

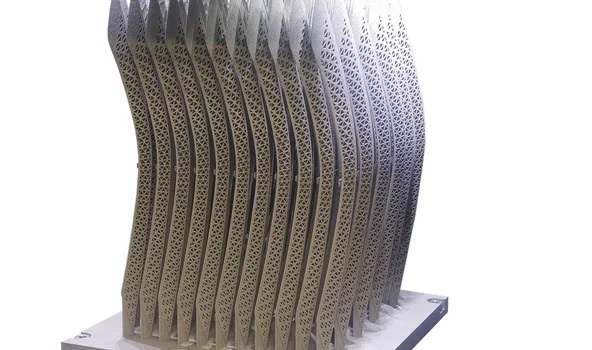

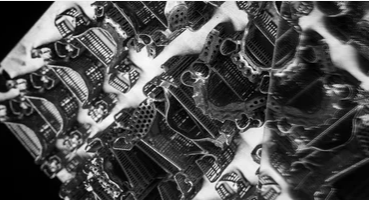

Example Applications 3D-Printed Parts From the EOS M 290

Material Management Metal Materials

The EOS powder handling portfolio offers a wide range of products for advancing and sieving metal powder. The products have different degrees of automation, are suited for small or large powder quantities and can be used flexibly and independently of the respective EOS metal system.

IPCM-M extra

The IPCM-M extra is the manual solution that is flexible in use with multiple machines, easy to scale-up with increasing demand and can be used with all EOS metal systems.

IPCM-M pro

The IPCM-M pro is a semi-automatic solution that secures easy, fast and safe handling in a closed system. It reduces the steps in the powder handling workflow while keeping the flexibility to use it with multiple machines.

Metal Materials for the EOS M 290

The EOS M 290 has the most extensive range of validated materials and processes on the market.

EOS StainlessSteel

Stainless steel alloys are used in many industries, including aerospace, medicine, energy, jewelry, shipbuilding, and the food sector. The chemical and mechanical properties of our alloys meet various international material standards.

EOS Aluminum

Aluminum alloys are ideal for many applications in the aerospace and automotive industries. The chemical and mechanical properties of our alloys meet various international material standards.

EOS CobaltChrome

Cobalt-chrome is often used in aerospace and medical applications. Two of these materials are certified for dental restoration, e.g. crowns, bridges, and denture components. The chemical and mechanical properties of our alloys meet various international material standards.

<h3″>EOS NickelAlloy

Nickel alloys can be used in a variety of applications: aircraft, gas turbines, and shipbuilding. The chemical and mechanical properties meet various international material standards.

EOS Titanium

Various high-performance applications in the aerospace, automotive, and medical industries use titanium for its properties. The chemical and mechanical properties of our alloys meet various international material standards.

EOS Copper Cu

High purity copper for the EOS M 290 to reach good electrical and thermal conductivity for a wide variety of applications.

EOS CaseHardeningSteel 20MnCr5

Case hardening steel with good hardenability reaching good wear resistance due to high surface hardness after heat treatment.

Software

EOS offers tried-and-tested software solutions for all process steps in additive manufacturing – from the preparation of CAD design data and job preparation to quality control.

EOSTATE Monitoring

EOSTATE is the modular solution for seamless monitoring of all production and quality-relevant data in industrial 3D printing. EOSTATE comprises 4 modules that can be used individually or in combination.

EOSPRINT 2

EOSPRINT is an intuitive, open and productive CAM tool for EOS systems that enables the assignment and optimization of build parameters for your CAD data. Together with data preparation software like SIEMENS NX or Magics, it offers an extensive additive manufacturing CAM environment for a smooth 3D printing process.

EOSCONNECT Core

EOSCONNECT Core is the connectivity solution for monitoring production. EOS systems are IIoT-capable and can be integrated into existing IT infrastructures via EOSCONNECT Core. EOS offers an open interface for this.

EOSCONNECT MachinePark

Expand the capabilities of your EOS system. Increase your productivity with EOS Web Apps and monitor your entire EOS machine park from anywhere in an intuitive dashboard. Receive automatic notifications on machine status and print jobs.

Our Webinar