EOS M 100

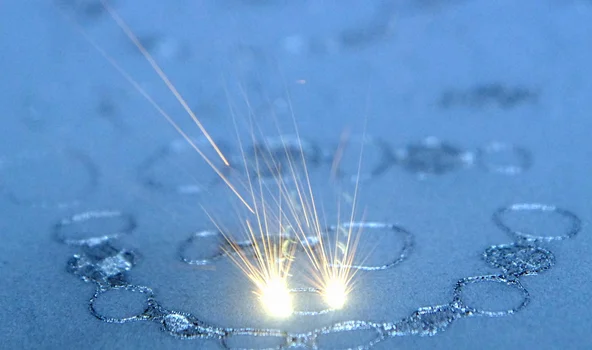

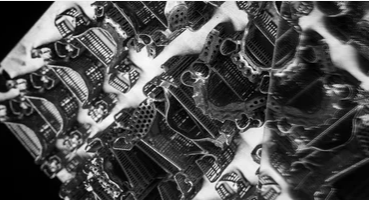

Small laser spot for complex and delicate parts

200-watt fiber laser for consistent part quality

Especially suitable for medical applications

Laser Power

The power stability of the 200-watt fiber laser ensures optimal and consistent processing. The small laser spot with excellent detail resolution is ideal for manufacturing highly complex, delicate parts.

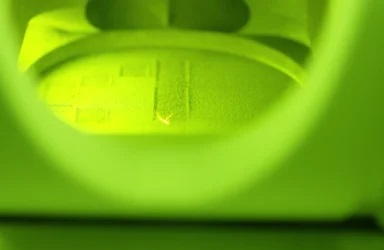

Build Space

With its small build space on a round construction platform of 100 mm in diameter, the system is primarily geared towards cost-efficient production in small quantities.

Accessories

Setup and cleanup are possible in just a few minutes thanks to the modular inner structure and the powder bed container. The material is easy to switch and maintenance is quick to perform.

EOS M 100Technical Data |

||

| Construction Volume | Ø 100 x 95 mm (Ø 3.9 x 3.7 in) (height incl. build plate) | |

| Laser Type | Yb-fiber laser; 200 W | |

| Precision Optics | F-theta-lens; high-speed scanner | |

| Scan Speed | up to 7.0 m/s (23 ft./sec) | |

| Focus Diameter | 40 µm (0,0016 in) | |

| Power Supply | 200 – 240 V | |

| Power Consumption | max. 1.7 kW / average 0.60 kW | |

| compressed air supply | max. 4,000 hPa, 50 l/min | |

| Machine Dimensions (W x D x H) | 800 x 950 x 2,250 mm (31 x 37 x 89 in) | |

| Recommended Installation Space | min. 1.00 x 3.00 x 2.5 m (3 x 10 x 8 ft) | |

| Weight | 580 kg | |

| Software | EOSPRINT, EOS RP Tools, Cambridge or Materialise Magics Metal Package and modules |

The EOS M 100 system is part of the portfolio of additive metal systems that we use ourselves for development. The system is characterized by ease-of-use when handling powder and exchanging powder components. It has great potential for reducing set-up times, increasing productivity and improving ergonomics and safety for machine operators.

Metal Materials for the EOS M 100

The EOS M 100 offers a certified portfolio of materials with a special focus on medical applications.

EOS CobaltChrome

Cobalt-chrome is often used in aerospace and medical applications. Two of these materials are certified for dental restoration, e.g. crowns, bridges, and denture components. The chemical and mechanical properties of our alloys meet various international material standards.

EOS StainlessSteel 316L

Parts show a high level of corrosion resistance, toughness and ductility as well as a high resistance to acids.

EOS Titanium Ti64

Titanium’s material characteristics make it ideal for many high-performance applications in aerospace, automotive & medical.

Tungsten W1

The refractive materials family of powders encompasses EOS Tungsten W1, a pure tungsten alloy, which is designed and tested for use on EOS’ metal systems.

Software

EOS offers tried-and-tested software solutions for all process steps in additive manufacturing – from the preparation of CAD design data and job preparation to quality control.

EOSPRINT 2

EOSPRINT is an intuitive, open and productive CAM tool for EOS systems that enables the assignment and optimization of build parameters for your CAD data. Together with data preparation software like SIEMENS NX or Magics, it offers an extensive additive manufacturing CAM environment for a smooth 3D printing process.