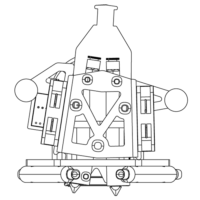

Delta WASP 4070 INDUSTRIAL X

Delta WASP 4070 INDUSTRIAL X

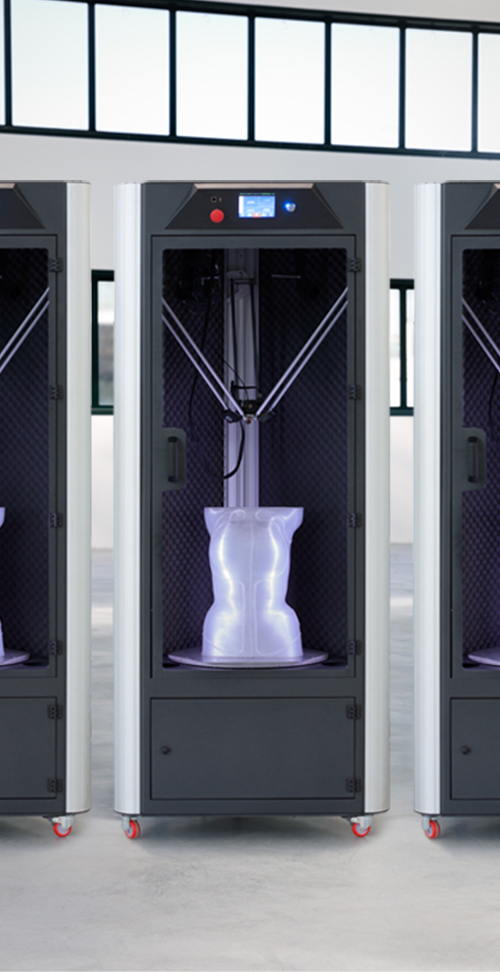

Manufacture parts quickly using the strongest technical materials with professional 3D printer Delta WASP 4070 INDUSTRIAL X. Thanks to the new system featuring a heated chamber and cooled mechanics, printing technical materials it’s even easier.

ΤΕΧΝΙΚΕΣ ΛΕΠΤΟΜΕΡΕΙΕΣ

Όγκος χτισίματος: Ø400 x h 700 mm

Θερμαινόμενος θάλαμος: Θερμαίνεται μέχρι 70°C

Ελάχιστο ύψος στρώσης: 100 micron

Μέγιστη ταχύτητα εκτύπωσης (*): 200 mm/s

Travel speed max (*): 300 mm/s

Επιτάχυνση (*): 6.000 mm/s2

Μέγιστη θερμοκρασία πλάκας: 120 C°

Διάμετρος ακροφύσιου standard: WASP ZEN X Extruder with MT cartridge, nozzle 0,7 mm

* Όλες οι προδιαγραφές σχετικά με την ταχύτητα σχετίζονται με έναν Delta WASP 4070 Industrial X με εξωθητή WASP ZEN X 0.4 mm.

Κατάλληλα νήματα

Ø1.75 με εξωθητή “WASP ZEN X”

Ø2.85 με εξωθητή “WASP FLEX”

ASA

ABS

HIGH-IMPACT PS

PETG

POLYCARBONATE

PC+ABS

PPS

PMMA

PVA

PA

PA carbon

PLA

TPU *μόνο με εξωθητή FLEX

TPE *μόνο με εξωθητή FLEX

POLYPROPYLENE *μόνο με εξωθητή FLEX

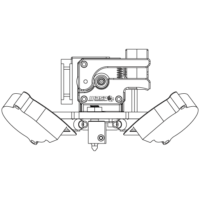

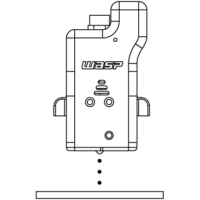

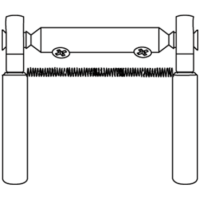

WASP ZEN X Extruder: dual extruder for single material, multicolor or multimaterial prints, with end filament sensor.

Nozzle diameter: 0.4 mm, 0.7 mm, 1.2 mm (filament diameter 1.75 mm)

WASP FLEX Extruder: direct drive extruder for flexible materials down to shore 50A.

Nozzle diameter: 0.4 mm, 0.7mm (filament diameter 3 mm)

Λειτουργικό σύστημα: WIndows, Mac, Linux

Λογισμικό κοπής: συμβατός με όλα τα λογισμικά κοπής (Cura – SLic3r – Simplify3D®)

Περιβάλλον εργασίας λογισμικού: Printrun – Repetier Host

Τύπος αρχείων: .stl, .obj, .gcode

Pendrive USB

Wifi network

Display TFT touch

Διαστάσεις: 85 cm x 77 cm x 195 cm

Διαστάσεις: 90 kg

Διαστάσεις αποστολής με ξύλινη συσκευασία: 100 cm x 100 cm x 230 cm, Βάρος 250kg

Είσοδος: 220/240 V 50/60 Hz;

Κατανάλωση ισχύος:

_WASP ZEN X Extruder: 120 W max

_Hot bed: max 1300 W

_Room heater: max 1500 W

Χρήση: 20-30 C°;

Αποθήκη: 0-30 C°;

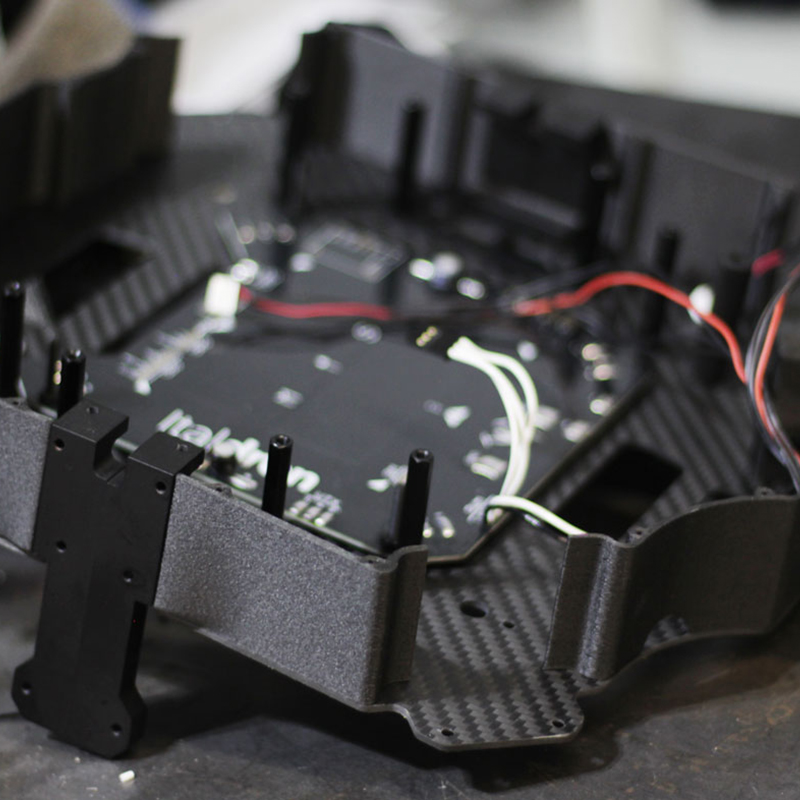

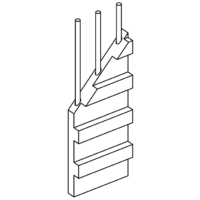

Frame and cover: aluminum, steel, polycarbonate, PU. All metal body for a stiff and vibration free precise machine

Bed: machined aluminum

Movements: nylon wheels on anodized aluminum sliders PU steel core belts, resistant to high temperature

Insulation: polymer foam for thermo-acoustic insulation

Motors: Stepper

Continuous Print: when the used extruder runs out of filament, the print continues with the other extruder (if correctly loaded)

Bed safety sensor: automatic system that avoids the collision of the extruder on the plate. automatic security system.

Gcode analyzer: gcode error checking system.

Auto check: automatic error recognition routine.

Mesh auto calibration: mesh plate calibration.

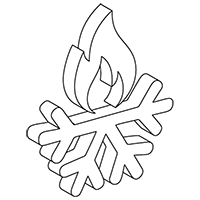

Hot and Cold tecnology: heated chamber and cooled mechanics.

WIFI: machine connected to the network for monitoring and control.

New GUI: new touch interface with bigger TFT display.

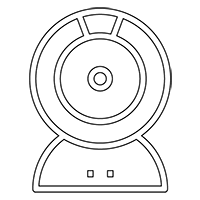

Camera on-board: for monitoring and timelapse.

Remote support: WASP technicians can work remotely on your machine in case of issues.

Hot and Cold tecnology: heated chamber and cooling of the mechanics

WIFI: machine connected to the network for monitoring and control

New GUI: new touch interface with bigger TFT display

Camera on-board: for monitoring and timelapse

Remote intervention: WASP technicians can work from remote on your machine in case of issues

HOT & COLD TECHNOLOGY (cc)

An efficient way of heating by two internal heat sources, makes possible to ensure work temperatures up to 80 °C, without burdening the mechanical parts of the machine.

ΣΥΣΤΗΜΑ RESURRECTION (cc)

Ένα σύστημα που επιτρέπει στους χρήστες να αποθηκεύσουν την εργασία εκτύπωσης για να το συνεχίσουν σε περίπτωση διακοπής ρεύματος. Διαβάστε περισσότερα

ΣΥΣΤΗΜΑ FREE ZETA (cc)

Επιτρέπει την εκτύπωση ενός αρχείου ξεκινώντας από ένα ακριβές ύψος του μοντέλου που θα εκτυπωθεί, το ύψος που επιλέχθηκε προηγουμένως. Διαβάστε περισσότερα

1kg of PLA in spool

Packaging for national/international shipping in wooden box (100 cm x 100 cm x 230 cm, peso 250 kg).

Βιομηχανικά εργαλεία

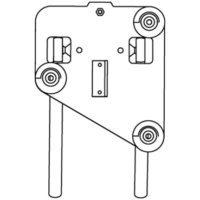

Dual extruder WASP ZEN X Extruder for single and multi-material prints. Different materials from 0 to 350 ° with the same cartridge and with the possibility to easily switch nozzles with multiple diameters.

Swapping the WASP ZEN X Extruder for the WASP FLEX Extruder to print soft materials (up to shore 50A) takes only few minutes.

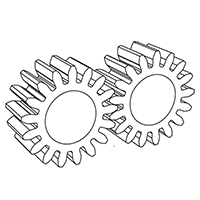

The external Bowden replaces the suspended thanks to the new “Filament driver X”. The grip on the filament is doubled and the force tripled thanks to two hardened steel gears and a gearbox.

ΕΞΩΘΗΤΗΣ

WASP FLEX

Για πολύ μαλακά και

ευέλικτα υλικά.

Ø 0.4 mm

WASP ZEN X

EXTRUDER

Double extrusion to

double the possibilities.

Ø 0.4 mm, 0.7 mm, 1.2 mm

ΧΑΡΑΚΤΗΡΙΣΤΙΚΑ

ΑΥΤΟΡΥΘΜΙΖΟΜΕΝΟ

ΣΥΣΤΗΜΑ

ΑΙΣΘΗΤΗΡΑΣ

ΤΕΛΕΙΩΜΑΤΟΣ ΝΗΜΑΤΟΣ

PRINT VIA

USB

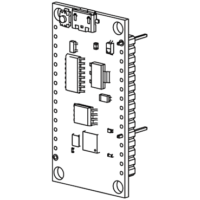

NEW 32 BIT

BOARD x4 POWER

ΚΛΕΙΣΤΟΣ ΘΑΛΑΜΟΣ ΜΕ

ΘΕΡΜΟΑΚΟΥΣΤΙΚΗ

ΜΟΝΩΣΗ

DUAL GEAR

FILAMENT DRIVER

LIVE VIEW

CAMERA

VIDEO TUTORIAL

ON BOARD

ΑΙΣΘΗΤΗΡΑΣ ΑΣΦΑΛΕΙΑΣ

ΑΝΟΙΧΤΗΣ ΠΟΡΤΑΣ

ΥΨΗΛΟΤΕΡΗ

ΘΕΡΜΟΚΡΑΣΙΑ

MULTICORE AUTOMATIC

EXTRUDER RECOGNITION

ADJUSTABLE ZERO

PLAYS SCROLL

PIANO FIBRAL

RECTIFIED

PRECISE HEAT

RESISTANT MECHANICS

ΑΤΣΑΛΙΝΕΣ ΖΩΝΕΣ ΓΙΑ

ΥΨΗΛΕΣ ΘΕΡΜΟΚΡΑΣΙΕΣ

IMPROVED

USER INTERFACE

HOT & COLD

TECHNOLOGY

ΜΟΝΑΔΑ WIFI ΓΙΑ

ΤΗΛΕΧΕΙΡΙΣΜΟ

ΔΩΡΕΑΝ ΣΥΣΤΗΜΑ

ZETA (cc)

ΣΥΣΤΗΜΑ

RESURRECTION (cc)

Βιομηχανικός 3d εκτυπωτής

Delta WASP 4070 INDUSTRIAL X is manufactured in metal with strong steel core belts and features a thermal and acoustic insulation.

“Hot and Cold technology” allows the control of room temperature up to 70°C and cools down the mechanics making the print of technical materials easier.

Delta WASP 4070 INDUSTRIAL X can be connected to Wifi network so that you can manage your printer from smartphone, tablet or PC.

Inside the printer there’s now a camera for monitoring the print even from afar.

ΝΗΜΑΤΑ 3D ΕΚΤΥΠΩΣΗΣ

WASP PLUS +

ΥΨΗΛΗ ΑΝΑΛΥΣΗ

100 Micron

ΤΕΡΑΣΤΙΟΙ ΟΓΚΟΙ

Ø 400 mm x 700 mm = 28 l

ΥΨΗΛΗ ΤΑΧΥΤΗΤΑ

Μέγιστη ταχύτητα εκτύπωσης: 200 mm/s

Maximum travel speed: 300 mm/s

Επιτάχυνση: 6.000 mm/s2

ΘΕΡΜΑΙΝΟΜΕΝΟΣ ΘΑΛΑΜΟΣ

Μέγιστη θερμοκρασία: 70°

ΥΨΗΛΗ ΘΕΡΜΟΚΡΑΣΙΑ

Μέγιστη θερμοκρασία εξωθητή: 350°

WIFI REMOTE

WIFI: machine connected to the network for monitoring and control

New GUI: new touch interface with bigger TFT display

Camera on-board: for monitoring and timelapse

Remote intervention: WASP technicians can work from remote on your board in case of issues

ΠΟΛΛΑΠΛΑ ΥΛΙΚΑ

ASA – ABS – HIGH-IMPACT PS – PETG – TPU – TPE – POLYPROPYLENE – POLYCARBONATE – PC+ABS – PPS – PMMA – PVA – PA – PA carbon – PLA

FIRMWARE UPDATE

Continuous Print: when the used extruder runs out of filament,

the print continues with the other extruder

Bed safety sensor: automatic security system

Gcode analyzer: gcode error checking system

Auto check: automatic error recognition routine

Mesh auto calibration: mesh plate calibration

HOT AND COLD TECHNOLOGY (cc)

An efficient way of heating by two internal heat sources, makes possible to ensure work temperatures up to 80 °C, without burdening the mechanical parts of the machine.

ΣΥΣΤΗΜΑ RESURRECTION (cc)

Ένα σύστημα που επιτρέπει στους χρήστες να αποθηκεύσουν την εργασία εκτύπωσης για να το συνεχίσουν σε περίπτωση διακοπής ρεύματος. Διαβάστε περισσότερα

ΣΥΣΤΗΜΑ FREE ZETA (cc)

Επιτρέπει την εκτύπωση ενός αρχείου ξεκινώντας από ένα ακριβές ύψος του μοντέλου που θα εκτυπωθεί, το ύψος που επιλέχθηκε προηγουμένως. Διαβάστε περισσότερα

Industry 4.0

3D εκτυπωτής με πιστοποίηση CE για συμβατότητα με τα κίνητρα της Industry 4.0.