Crane WASP

The Infinite 3d printer

Crane WASP, a collaborative 3D printing system capable of printing houses, contained in the Maker Economy Starter Kit, print material found at Km 0 as our guide symbol: the vasaia wasp.

TECHNICAL DETAILS

Printing volume: Ø6300mm x h3000 mm

Minimum layer height: 9 mm

Maximum printing speed: 300 mm/s

Maximum travel speed: 500 mm/s

Acceleration: 20 mm/s2

Nozzle diameter: from 18 to 30 mm

Earth based materials

Concrete mortar

Geopolymers

LDM WASP XL EXTRUDER: nozzle diameter from 18 to 30 mm

Operative systems: Windows

Slicing software: Grasshopper

File type: .gcode

WiFi remote control

Dimensions: column height 4050 cm, arm length 3300 cm

Machine weight: 150 kg

Input: 220/240 V 50/60 Hz

Absorbed power: 1500 W

Use: 10-40 C°

Warehouse: 0-30 C°

Frame: Steel, aluminium

Crane WASP

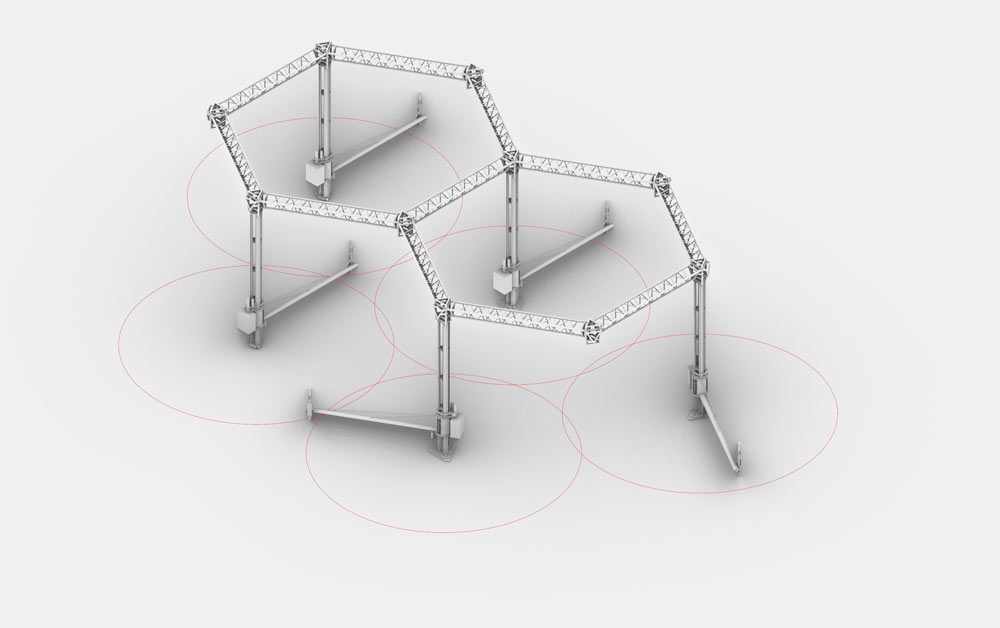

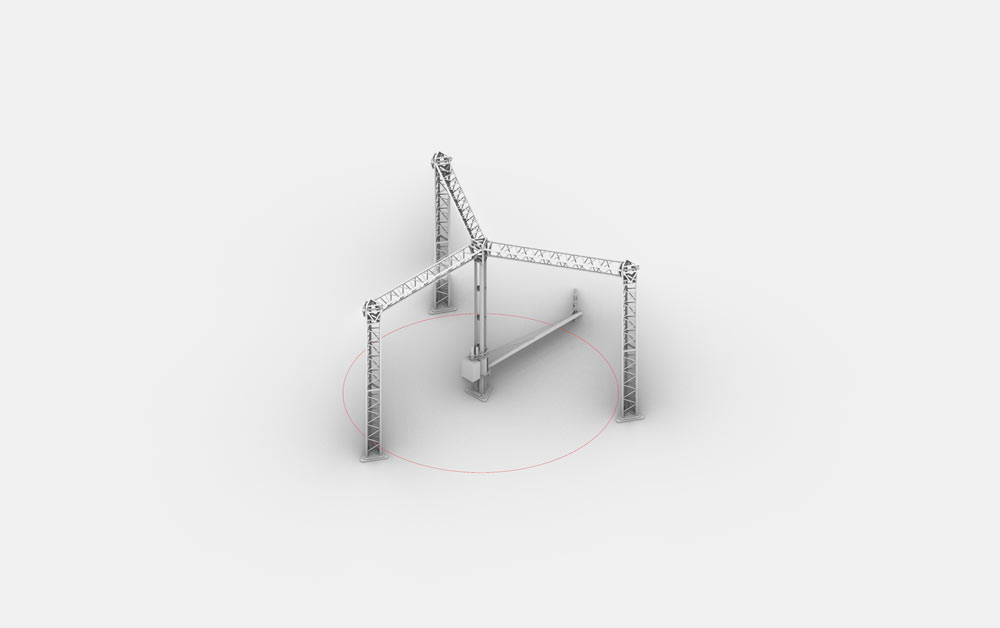

Crane WASP The Infinity 3d printer is a modular collaborative 3D printing system. It reinterprets the classic building cranes from a digital manufacturing point of view. It is composed of a main printer unit that can be assembled in different configurations depending on the printing area and therefore on the dimensions of the architectural structure to be calculated in 3d. The print area of the single module is 6.60 meters in diameter for a height of 3 meters.

The single module can work self-sufficiently by printing fluids of different kinds: cement, bio cement, natural dough. Once you have a single module, you can expand it by adding traverses and printer arms, thus generating an infinite digital manufacturing system.

It is not necessary to “cover” the entire area involved in the construction with the printing area of the WASP Cranes because they can be reconfigured and can advance with generative attitude depending on the growth and shape of the building. More WASP Cranes, when working together, have a potentially infinite printing area and can be set by the on-site operators following the evolution of the architectural project.

3d Printer House

The evolution of the Big Delta 12MT allows us to reduce the mechanical dimensions of the printer while maintaining a large print area. Created with the same modular mechanical components used to make up the Big Delta 12M aluminum structure , it is a fast and efficient tool to be dismantled and reassembled for an easy transport.

Contained in the Maker Economy Starter Kit, it too is designed to be able to print on-site natural mixes at 0km, with the addition of natural fibers for architectural-scale construction. The container, transported on site, offers all the necessary tools to build a self-sufficient village through the most advanced additive technologies. Depending on the territory and the project, one can choose the optimal printing configurations, by assembling each single module in different ways. All components are transported disassembled. The basic tools included in the kit together with the printer, are those dedicated to the mixture: muller and tumbler

GAIA

The first house 3D printed with earth